Experts In Dimensional Inspection and Visual Defect Detection

Geometries EV Battery & Ammunition (AI Defect Detection)

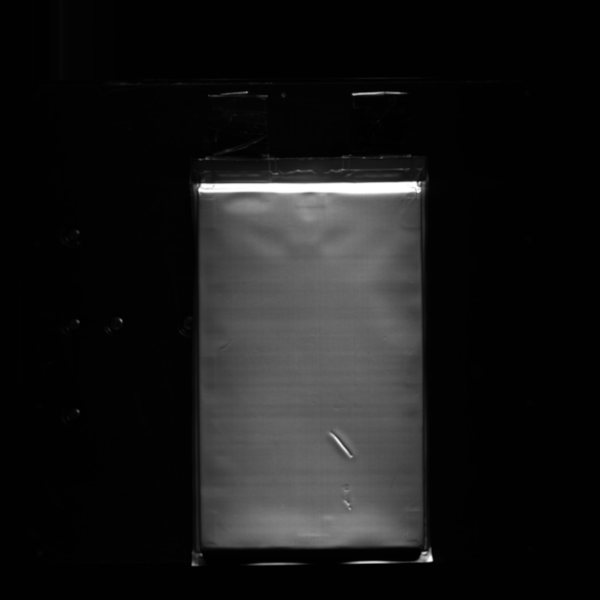

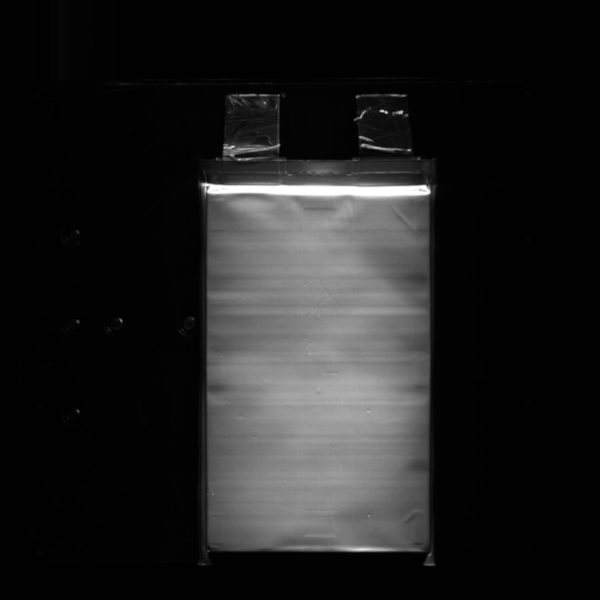

100% defect free raw materials and battery cells

- Reduction of scrap and waste using vision-based quality control

- Material reduction through machine vision sensors and software algorithms

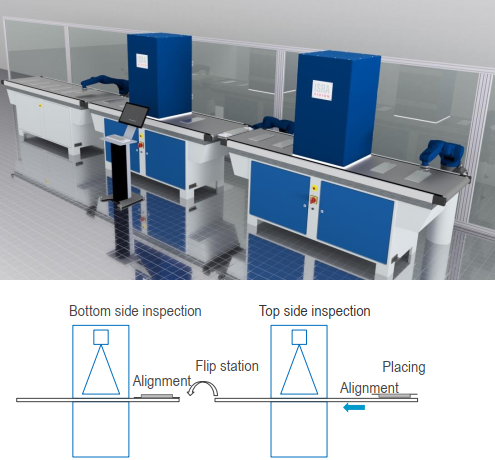

Production and assembly of EV batteries

100% defect free raw materials and battery cells.

Reduction of scrap and waste using vision-based quality control.

Material reduction through machine vision sensors and software algorithms.

Fastest and most accurate ammunition inspection machine available

Complete line of gauging, sorting, and inspection systems incorporating: laser, eddy current and vision technologies for dimensional measurement, determining metallurgical defects as a method for achieving zero defects. Gauging, inspection and sorting systems assure quality in product size, shape and structure.

Surface defect detection is a common Quality Control Parameter followed in almost all industries for their parts. Manual identification is tedious and expensive. Today’s machine vision systems don’t offer the accuracies and consistencies that are required. Our specially designed solution for Surface Anomaly Detection offers the combination of easy training and highly accurate detection making even the most challenging detection application a breeze.

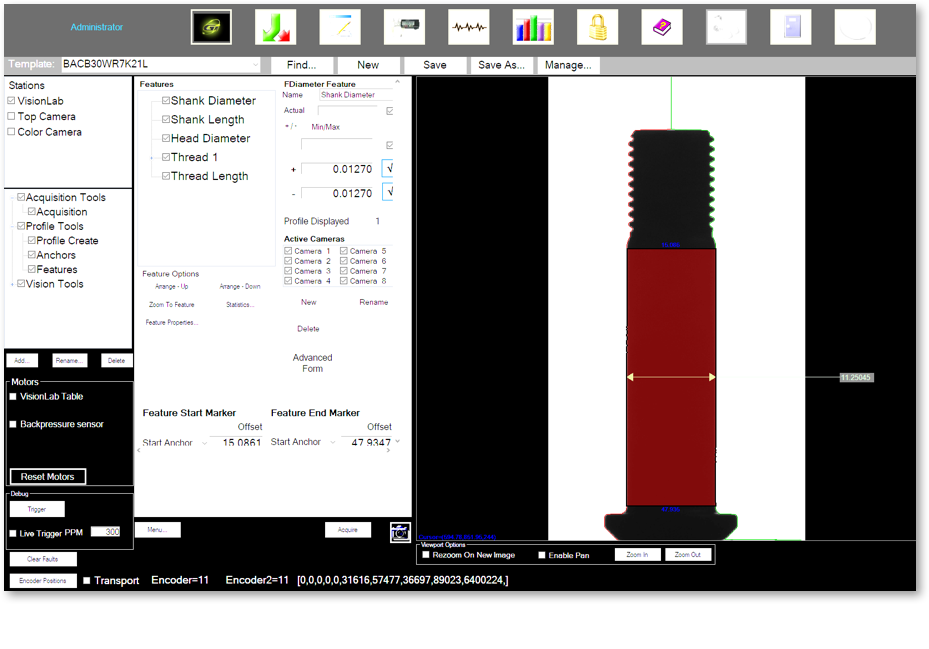

Ammunition Case Inspection System

Measures Small and Medium Caliber Bullets, Cases & Cartridges

This system has been and continues to be implemented in factories world-wide by companies fulfilling government contracts for the military as well as companies servicing the commercial ammunition industry.

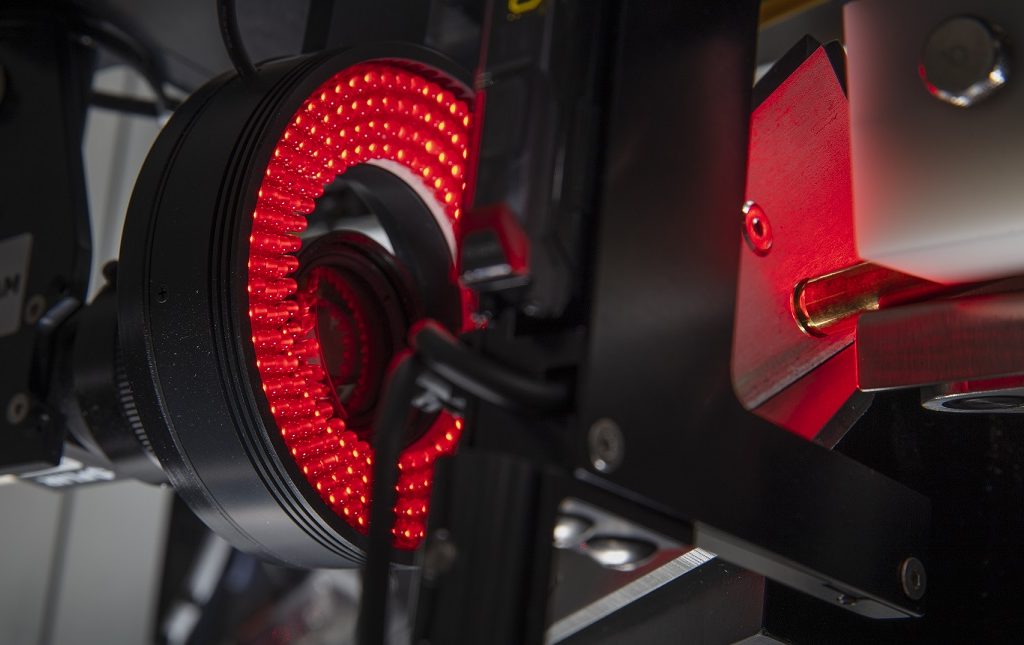

The 6V will inspect cases, projectiles and/or loaded cartridges. Employing Laser Gauging, Vision and Eddy Current technology combined with user-friendly, menu driven Windows based software this machine will measure all outside dimensions, mouth defects, primer defects, and case surface defects at a rate of 300 per minute!

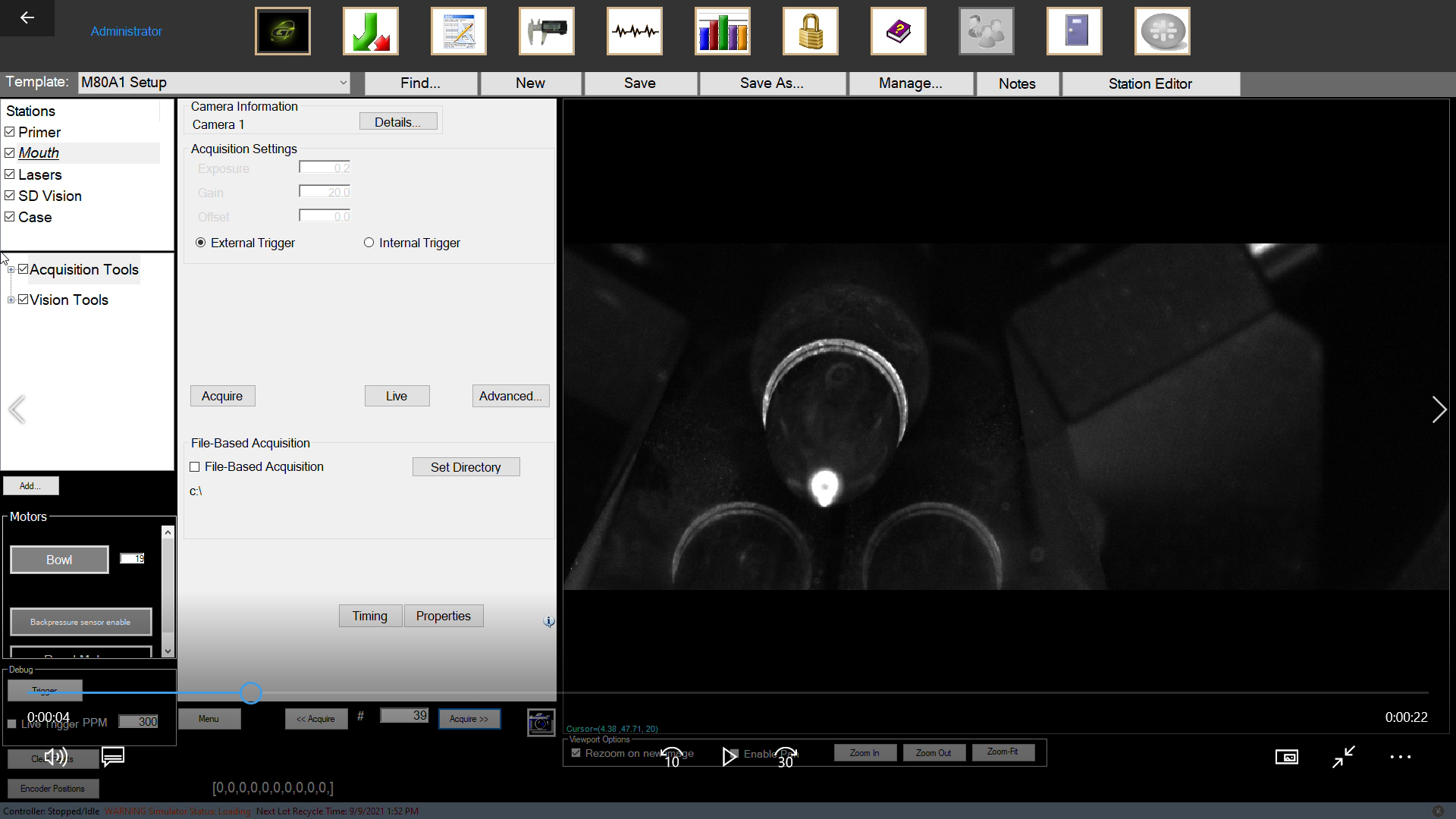

Primer Vision

Primer Vision is on axis to detect visual defects.

Detects

• Head stamp presence

• Flash hole presence

• Primer pocket diameter

• No primer lacquer

• Missing inverted, cocked dented primers

Mouth Vision

Measures and detects defects on the mouth end, such as wall thickness, roundness and splits.

Detects

Cases

• Splits, Lip mouth, Out of round

• Measures mouth inner

• Measures outer diameter

Cartridges

• Mixed or damaged HPT and FMJ bullets

3D Primer Depth