Cleanroom Measuring Devices: Precision for Controlled Environments

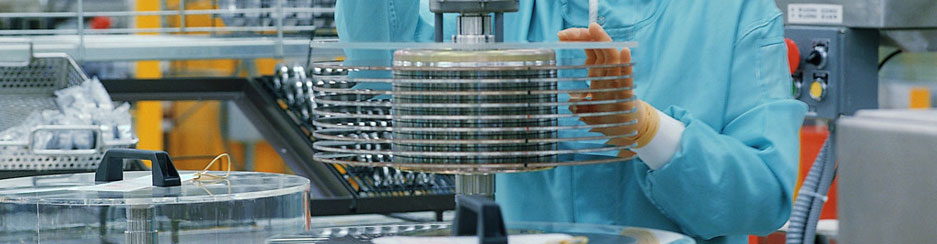

In industries where air purity, particle count, and environmental conditions are critical, cleanroom measuring devices play a vital role in maintaining compliance and product integrity. These specialized instruments are designed to monitor and measure key parameters in controlled environments such as cleanrooms, labs, pharmaceutical manufacturing, semiconductor production, and biotechnology facilities.

What Are Cleanroom Measuring Devices?

Cleanroom measuring devices are high-precision instruments used to monitor critical environmental parameters, including:

- Particle Counters: Measure airborne particles to ensure ISO cleanroom classification.

- Differential Pressure Gauges: Monitor pressure differences between cleanroom zones.

- Air Velocity Meters / Anemometers: Measure laminar flow and airflow velocity.

- Temperature & Humidity Meters: Maintain optimal conditions for sensitive processes.

- Microbial Air Samplers: Detect and quantify microbial contamination.

- Surface Electrostatic Testers:Surface Electrostatic Testers: Ensure static control in ESD-sensitive environments.

MANUFACTURER

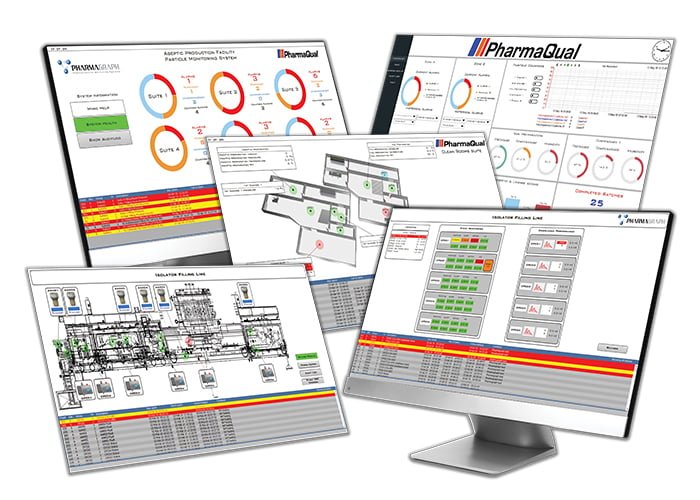

We have been engaged in sales, technical support, maintenance, and software development as a distributor in Thailand for than 20 years since 1999. Our solutions have been adopted in clean rooms in various industries, including pharmaceutical industry. Our support covers from introduction to operation including validation support.

Gyroscope Tech has been marketing and maintaining products related to clean rooms such as pharmaceuticals and semiconductors for more than 26 years.

We also develop management systems for multi-point environmental monitoring and filter integrity testing for sterile filtration complying with the regulatory requirements, such as data integrity. We represent variety of leading manufacturers, and can help you improve your day-to-day operations.

Why They're Essential

✔️ Regulatory Compliance: Meet ISO 14644, GMP, and FDA standards. ✔️ Product Quality Assurance: Prevent contamination that can compromise product safety or efficacy. ✔️ Process Stability: Control variables that impact precision manufacturing. ✔️ Audit Readiness: Ensure traceability with calibrated, validated measurement tools.

Applications

Cleanroom measuring devices are commonly used in:

- Pharmaceutical & Biotech Manufacturing

- Semiconductor & Electronics Assembly

- Medical Device Production

- Aerospace & Optics Industries

- Research Laboratories

Certified Accuracy & Calibration

All our cleanroom instruments are:

- Factory-calibrated and traceable to national standards

- Compliant with ISO/GMP requirements

- Available with on-site or lab calibration services

Contact Us for Cleanroom Measurement Solutions

Let us help you choose the right instruments for your cleanroom environment. Contact Us