What Is Electrical Surface Resistivity?

Electrical surface resistivity is the electrical resistance of the surface of a material, expressed in Ohms per Square (Ω/sq). It is independent of the material’s size or thickness. Surface resistivity is calculated based on the surface resistance of the material and the known geometry of the electrodes. It represents the material’s resistance to current flow when an electrical potential difference is applied across its surface. Unlike volume resistivity, surface resistivity specifically addresses the electrical characteristics of a material’s surface layer, affecting its behavior in applications such as coatings, films, and insulating layers.

Factors influencing surface resistivity include material composition, surface treatments, moisture, temperature, contamination, and mechanical stress. These factors impact the surface’s conductivity or insulation properties.

Testing Principle and Methodology

Place two electrodes of equal length on the material’s surface, spaced at a known distance. Apply a direct current voltage to one electrode and measure the resulting current at the other. Alternatively, you can use a concentric test cell with a known cell constant. Use a megger-ohmmeter to measure the resistance directly. Then, calculate the surface resistivity using the formula:

Surface Resistivity Calculation Formula Where:

ρ = Resistivity in ohms per square (Ω/sq)

R = Measured resistance

L = Length of electrode

D = Distance between electrodes

Testing is typically conducted on solid materials in their commercial form and under varying humidity conditions.

Factors such as temperature, relative humidity, and surface cleanliness can affect measurement accuracy. It is critical to ensure the surface is clean and free from contamination to avoid skewed results.

Applicable StandardSurface resistivity testing is performed according to these standards:

ASTM D257: Standard Test Methods for DC Resistance or Conductance of Insulating Materials

BS 5958: Part 1: 1991

BS 7506: Part 2: 1996

NFPA 77

Data InterpretationSurface resistivity values are classified as follows:

< 10⁵ Conductive / Low Resistivity

10⁵ to 10⁹ Static Dissipative / Medium Resistivity

> 10⁹ Non-Conductive / High Resistivity

Knowing your material’s surface resistivity enables safe handling measures. Materials should be handled in a well-earthed environment to prevent electrostatic charge buildup. Sudden discharge of accumulated charge can ignite flammable atmospheres, so understanding electrostatic properties is crucial to preventing such hazards.

We also offer:

Volume Resistivity

Surface Resistivity

Charge Decay (Relaxation) Time

Electrostatic Discharge (ESD) Testing

Breakdown Voltage

Liquid Conductivity Testing

Flexible Intermediate Bulk Containers (FIBC)

Electrostatic Chargeability Testing

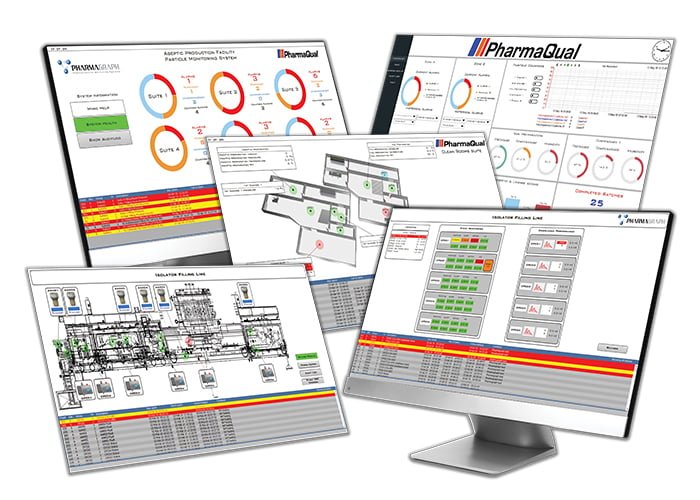

In industries where air purity, particle count, and environmental conditions are critical, cleanroom measuring devices play a vital role in maintaining compliance and product integrity. These specialized instruments are designed to monitor and measure key parameters in controlled environments such as cleanrooms, labs, pharmaceutical manufacturing, semiconductor production, and biotechnology facilities.

Cleanroom measuring devices are high-precision instruments used to monitor critical environmental parameters, including:

We have been engaged in sales, technical support, maintenance, and software development as a distributor in Thailand for than 20 years since 1999. Our solutions have been adopted in clean rooms in various industries, including pharmaceutical industry. Our support covers from introduction to operation including validation support.

Gyroscope Tech has been marketing and maintaining products related to clean rooms such as pharmaceuticals and semiconductors for more than 26 years.

We also develop management systems for multi-point environmental monitoring and filter integrity testing for sterile filtration complying with the regulatory requirements, such as data integrity. We represent variety of leading manufacturers, and can help you improve your day-to-day operations.

✔️ Regulatory Compliance: Meet ISO 14644, GMP, and FDA standards. ✔️ Product Quality Assurance: Prevent contamination that can compromise product safety or efficacy. ✔️ Process Stability: Control variables that impact precision manufacturing. ✔️ Audit Readiness: Ensure traceability with calibrated, validated measurement tools.

Cleanroom measuring devices are commonly used in:

All our cleanroom instruments are:

Let us help you choose the right instruments for your cleanroom environment. Contact Us